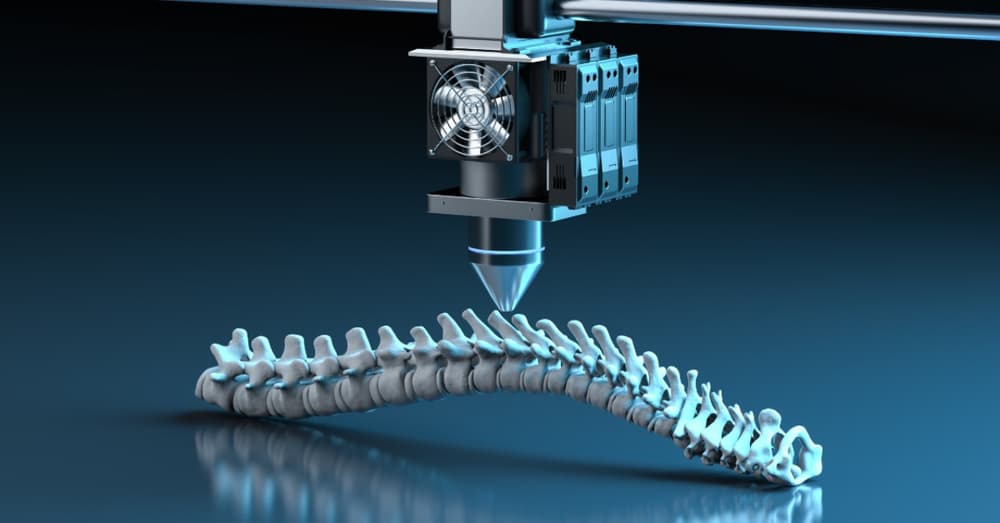

3D printing is transforming healthcare by enabling the creation of custom prosthetics and pioneering bioprinting of organs. Custom prosthetics offer a perfect fit, faster production, lower costs, and personalized designs, improving comfort and mobility for patients.

3D Printing in Healthcare: Custom Prosthetics and Bioprinting Organs

Written by Sumit Kaushik

Picture having your medical equipment and even your organs tailored to order just for you — shaped just so precisely to perfectly fit your body the exact same shape and size as your own self. Thanks to 3D printing technology, this is now no longer a dream but an inspiring reality that is transforming medicine today.

From prosthetic limbs tailored to order for mere restoration of mobility, To the revolutionary organ bioprinting that could be the end of transplants shortages, 3D printing is revolutionizing patient care at historic pace, customization, and creativity.

What is 3D Printing in Healthcare?

3D printing or additive manufacturing constructs three-dimensional products layer upon layer from computer models. In medical practice, the process enables fabrication of intricate medical devices, implants, prosthetics, and even tissue with unrivaled accuracy.

It starts with imaging scans such as CT or MRI that create detailed maps of anatomy. The maps instruct printers to construct patient-specific solutions tailor-made especially for individual patients.

Custom Prosthetics: Welcome Comfort-Fit Convenience and Mobility

Shelf prosthetics are usually slow to fit, taking hours, and are supported by some sacrifices in comfort. 3D printing abolishes all these limitations with the following:

- Ideal Fit and Function: Prosthetics are custom fabricated from the patient's anatomical information, providing an ideal fit that maximizes comfort and mobility.

- Historic Speed: What took months previously is now achieved within weeks, cutting patient waiting time exponentially.

- Cost-Effectiveness: 3D-printed prosthetics are typically far cheaper to produce, so sophisticated mobility aids are within reach of many more individuals across the globe.

- Aesthetic Personalization: Customers can customize color, texture, and pattern, so prosthetics are quicker than functional devices turn into fashion accessories.

- Lightweight Materials: New printing materials are lighter in weight but don't compromise on strength, so they don't feel as heavy to put on.

For instance, Open Bionics has developed low-cost, programmable bionic hands for children and adults that utilize cutting-edge robotics and 3D printing to provide greater dexterity and control.

Bioprinting Organs: The Regenerative Medicine Cutting Edge

The most groundbreaking application may be bioprinting — building living organs and tissues from bio-inks made up of cells and biocompatible materials.

- How It Works: Sheets of cells are printed with very high precision to replicate the very highly evolved structure of human tissue. The shapes have a potential to develop into functioning tissue over time under favorable biological conditions.

- Potential Applications: From skin transplantation and cartilage restoration to entire organs such as kidneys, livers, and hearts, bioprinting has the promise to make donor shortage of organs a thing of the past and minimize the possibility of organ rejection by utilizing the patient's own cells.

- Personalized Medicine: Organs printed according to this approach can be customized to the patient's own biological fingerprint, lowering immune rejection and optimizing transplant success.

- Challenges and Advances: Functional printed organs must yet emerge from laboratory stages, although printing simple tissues and organoids for screening and drug discovery purposes is promising achievements. Cross-boundary and cross-disciplinary collaborative research in stem cell biology, biomaterials, and print resolution propel this frontier forward.

Benefits of 3D Printing in Medicine

- Precision Medicine: Provides medical treatment directly where it is needed based on patient physiology and anatomy.

- Speed and Accessibility: Accelerates delivery of medical devices and minimizes cost.

- Innovation in Treatment: Allows for development of complex structures impossible to achieve with conventional manufacturing.

- Better Outcomes: Enhances comfort, functionality, and minimizes complications.

- Sustainability: Saves waste by producing only what is desired layer by layer.

Real World and Future Direction

Hospitals and research facilities worldwide are using 3D printing technology to simulate surgeries, design patient-specific models and implants for which surgeons practice complex procedures. Prosthetic companies are providing amputees with inexpensive, aesthetically pleasing, and efficient prosthetics. Bioprinting facilities race to produce the first transplanted, viable printed organ.

The future is:

On-Demand Printing: Portable hospital-based printers for on-demand printing of implants or prosthetics.

Organ Banks: Bioprinted organs on-demand for personalized transplants.

Hybrid Technologies: Combining 3D printing and artificial intelligence to create more sensitive, more intelligent health devices.

Global Health Impact: Accessible prosthetics and healthcare devices in low-resource environments.